There are many sound-absorbing materials that can improve the acoustics of a room in your home or office.

When we talk about sound absorption, we mean something very different from soundproofing: in fact, soundproofing serves to prevent noise from entering or leaving a given space.

While sound absorption allows us to improve the acoustics of a room by attenuating or completely reducing the annoying echo.

Without the echo, you are able to get a better, clearer sound within a room.

Let’s delve more into Soundproofing below.

Which Has More Sound Proofing Effects, Wood or Glass?

Glass is an outstanding soundproofing (or, as it is more formally known, sound insulation) material.

There are numerous reasons for this. For starters, it’s dense, which means there’s a lot of mass packed into a little space. Second, it is non-porous, which means that sound cannot pass through it.

Wood is excellent at sound absorption in general because it is porous and has a lot of air spaces to absorb sound.

To combat this, processed wood types like Medium Density Fiberboard (MDF) are designed to have a high density and mass while maintaining the natural porosity of the wood.

In a nutshell, the best soundproof wood types are Medium Density Fiberboard, Oriented Strand Board, Cork, and Acoustic Plywood.

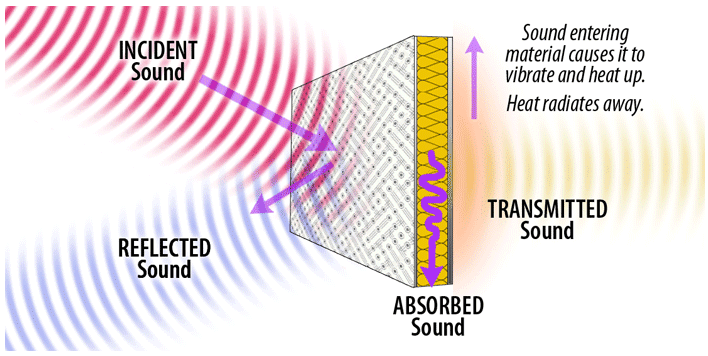

Sound absorption is achieved in various ways: by porosity, by resonance of cavities and by resonance of membrane (or absorbing panels).

Especially for the attenuation of medium and high frequencies, the most widely used sound-absorbing materials and more suitable to act to eliminate the echo are porous absorbers.

While the absorption by cavity resonance and membrane resonance absorption is obtained through more complex structural elements.

Porous sound-absorbing materials absorb the annoying echo using convective motions; they are divided into fibrous sound-absorbing materials and open-cell sound-absorbing materials.

Fibrous materials that absorb sound waves can be cork, glass wool, rock wool, chipboard, curtains, etc.; open-cell sound-absorbing materials absorb sound.

Instead, from the air movement of sound waves through the material passages: they can be expanded clay, expanded perlite, expanded polyurethane, and many others.

Does Concrete or Wood Block Sound Better?

Wood has a higher sound dampening potential than other structural materials due to this internal friction.

Although a concrete wall will reflect sound as well, it will do so in a much harsher manner, resulting in louder echoes.

Wood is one of the most widely used materials in construction since the beginning of time.

It is characterized by its good insulating and mechanical properties, in this case, we are going to analyze why wood is a good soundproofing material.

In construction, it is very rare that wood appears as a single material forming part of a wall, door, or floor, for example.

Normally solid wood is used together with other elements such as a board, which although it is composed of wood fibers, the set can vary its acoustic properties in relation to these two elements separately.

The acoustic insulation to a noise depends on the mechanical properties of the material and responds to the law of mass.

This law of mass relates the sound insulation of a material to the density of the material and the sound frequency.

According to this law, in the case of wood, the mass can be directly related to the density of the wood, a fact already studied for almost all species.

The density of wood represents the amount of mass in a given volume, which means that heavier woods (with more mass) have a higher density.

Therefore, construction elements manufactured with species of higher densities, such as tropical woods, will offer greater sound proofing strength.

As we said at the beginning, this sound proofing strength varies if more than one element is used; a product such as a door or floor that is composed of several sheets (board and wood for example).

in this case for the calculation of acoustic insulation does not follow the law of mass since it must be taken into account that there is a loss of energy by heat dissipation between the components of the element.

According to this principle, a porous structure such as wood absorbs mechanical energy transported by sound waves that are transformed into heat by friction, i.e. wood, due to its porous composition, absorbs the waves and transforms them.

Making it more difficult for them to pass through it and thus becoming a good acoustic insulator.

By this principle, the rigidity of the material affects the acoustic insulation.

The best way to improve sound insulation is to use floating coverings supported by elastic elements, such as false ceilings or false floors.

For example, the reduction of the noise level by falling objects with a multilayer parquet floor is around 20 dBA.

That is to say, if your upstairs neighbor has a parquet and an object falls to the floor, you will hear it less than if he had a ceramic floor.

Wood in construction, in addition to being a structural or constructive element, has a decorative or aesthetic function due to its beauty.

In many cases, it is used only for aesthetic reasons, as is the case of parquet, doors, or coatings, or only for structural reasons such as beams or decks.

But sometimes it is used to taking advantage of these two aspects; its properties as a material and its beauty as in the use of self-supporting wood panels.

Can Glass Walls Be Soundproof?

Soundproof glass is divided into three categories: It’s made of thick glass, as the name implies.

To deaden the sound, air holes are introduced between glass panels. Acoustic glass is a type of laminated glass that is made up of layers of glass, plastic, and glass.

Although each design has its own advantages, laminated and acoustic glass are the most energy-efficient and have the highest STC ratings.

The laminated and acoustic glass have the same construction and effect, but the resin used between each layer of glass and proprietary fabrication procedures differ.

Acoustic glass is a type of laminated glass that uses an acoustic variation of the PVB (polyvinyl butyral) used in most laminates.

In addition to soundproofing, PVE and EVA (ethylene-vinyl acetate) interlayers filter the majority of UV radiation.

The soundproof walls can also be mobile or compactable, so you can choose to have a single room or two separate rooms even acoustically. The models on the market are mainly made of wood or glass.

Soundproof walls made of glass have an average cost of 350 dollars/sqm (also depending on the type of glass used), while for the movable soundproof walls made of wood prices rise to 400-450 dollars/sqm.

Unfortunately, these solutions, ideal for companies, are not suitable for making movable walls for non-permanent or home recording studios.

The best soundproof walls for those who make music remain the fixed ones, suitably insulated with sound-absorbing polyurethane panels, to be combined with special sound-absorbing carpets.

Can You Use Regular Insulation For Soundproofing?

Insulation options for soundproofing include cellulose, fiberglass, and foam insulation, which can be mounted in your home’s walls, floors, and ceilings.

Outside sounds and noises from room to room and from various levels of your home or building are reduced with this form of insulation.

Sound absorption is not the same as sound insulation. In fact, both properties are often opposed to each other.

The porous materials that are introduced in the chambers of the enclosures (walls, facades, insulating panels, acoustic screens), do not provide hardly soundproofing by themselves.

However, they play a fundamental role in improving the acoustic insulation of the partitions.

On many occasions, we have heard and seen “that spongy yellow material”, “rock wool”, “fiberglass”, there are even those who call it “pica – pica” and installers and even technicians have been able to refer to it as “THE INSULATOR”.

Well, these materials with high porosity and low mass are usually excellent THERMAL insulators, but not acoustic insulators.

In general, materials with good thermal insulation properties incorporate a lot of air in their structure, so they have little mass.

This means that they cannot prevent the passage of acoustic energy through them, i.e. they do not insulate acoustically.

However, if their porous structure is open-cell (open-cell fibers or foams), they can have good acoustic absorption properties, which is the ability to convert part of the acoustic energy impinging on them into heat.

REFERENCES:

https://portella.com/blog/is-glass-soundproof/ http://www.rchd.cl/index.php/RDLC/article/download/2009/2083